RTR Job

The RTR job integrates in EIBPORT the complete range of functions of a room temperature controller.

Job Name

Required field. Assign a unique name for the job. The name must not contain more than 15 characters.

Gate Group Addresses

By Gate Group Addresses job will be released or blocked. The release object releases or locks the job. It is about an EIS1 object:

Field blank = Job is released.

Field completed, value 1 = Job released.

Field completed, value 0 = job locked.

Field completed, no value = job locked.

As soon as one address is filled in, release will behave respective to the value of the group address. If no value was sent to the address and the address is presently without values, job will be blocked.

Status Output (EIS14)

By that group address indicates the status of output objects:

0: No error,

1: Error on temperature sensor #1,

2: Error on temperature sensor #2.

Job Editor Classic - Job RTR

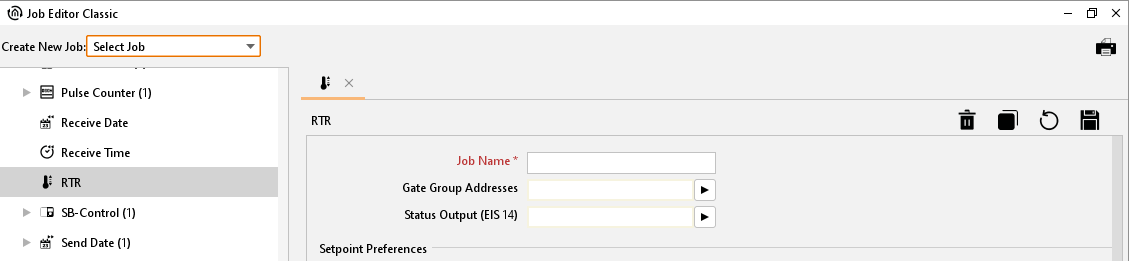

Mode of operation

Room temperature controller distinguishes various modes of operation. So, it is possible, to activate different temperature setpoints, for example depending on the absence of one person, the state of the heating- or cooling system, the time of the day or weekday.

Comfort:

Comfort operation should be activated, if personal will be present in the room and therefore room temperature must be adjusted to a comfortable suitable value.

Standby:

In case one room will be not in use during the day, because for example personal is absent, standby operation can be enabled. In this way room temperature can be adjusted to a standby value for saving heating or cooling energy.

Night operation:

During night operation or by extended absence it will be useful to adjust room temperature of heating systems to a lower temperature (for example in bedrooms). In this case, cooling plants can be justified to a higher temperature, if air conditioning is not necessary. (for example in offices).

Frost/heat protection:

Frost protection will be required for example, if room temperature should not come under critical values by open windows. Heat protection could be necessary if temperature will rise to high, in most cases by external influences of a steadily warm surrounding.

In these cases, freezing or overheating of the room can be prevented by activating the frost/heat protection, depending on the adjusted mode of operation “cooling” or “heating”.

Comfort extension

This is a kind of a party function, which could be used to hold comfort temperature for a certain time, for example if the room will be utilized during nighttime, too. One separate button will activate this function.

Summer compensation

For reasons of energy saving and for holding a comfort difference in temperature by entering an air-conditioned building in summer, an elevation of room temperature depending on outside temperature should be established.

In operating mode „Heating and cooling“, 6 temperature settings can be modified. In dependence on the parameterized temperature decrease, - increase or dead zone, all temperature set points deduce from the basis nominal temperature. Thereby attention should be paid to, that all other temperature set points will be modified by altering of the comfort nominal temperature for heating!

RTR Job – Funktional scheme

The dead zone (temperature zone in which neither heating nor cooling take place) is defined as the difference between the comfort temperature setpoint of “heating” and “cooling”. In this case it is valid:

TcomfortTargetCooling – TcomfortTargetHeating

=

Tdead zone; TcomfortTargetCooling ≥ TcomfortTargetHeating

Important hint:

In case of an assymetric position of the dead zone, only temperature settings of cooling will be altered by changing the cooling comfort temperature setting. It will be possible to alter the dead zone to 0 ° C by the help of a local operation. (TcomfortTargetCooling = TcomfortTargetHeating) In this way either heating or cooling proceed, if detected room temperature is equal to the comfort temperature setting.

Temperature settings of „standby“ and „night“ derive from the comfort temperature settings of heating and cooling. So, it will be possible to adjust temperature increase (for cooling) and temperature decrease (for heating) of both operation modes.

In- and output:

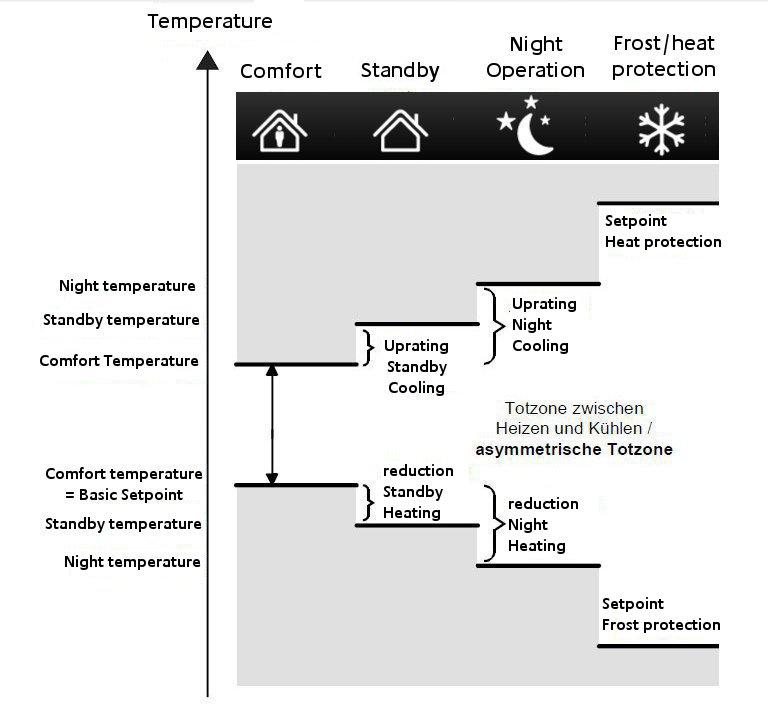

Setpoint Preferences

The room temperature should be able to be individually adjusted depending on a specified temperature range. For this purpose, is used the shift of the setpoint temperature.

A setpoint shift can be achieved in two ways.

Absolute setpoint shifting:

The setpoint is shifted within a lower limit or minimum temperature and an upper limit or maximum temperature. The settings for the setpoint adjustment are made with the DPT 9.001 (EIS5).Relative setpoint shifting:

The setpoint is shifted relative to a preset basic setpoint value. The setpoint is reduced or increased by the level to be specified. The temperature interval and the number of levels is configured in the settings. This means that the DPT 6.010 (EIS14s) is used.

The equal procedure must be set in the CONTROL L or CUBEVISION visualization according to the configuration. Due to the simpler control, the relative setpoint shift is preferable to the absolute one.

Job Editor Classic – RTR setpoint settings

Current setpoint Output (EIS5)

By this object current setpoint will be adjusted

Setpoint sending-interval:

In case setpoint will be sent cyclical, here desired time can be parametrized.

Basis Setpoint (Comfort):

This setpoint functions as a reference value, if no group address was assigned to basis setpoint input or no value still was sent to it.

Basis Setpoint Input (Comfort):

With the help of this object the basis setpoint can be adjusted, e.g., by an external RTR.

Setpoint Adjustment Input (EIS14s):

This object serves as a small step adjustment of the setpoint (see setpoint adjustment step).

Setpoint Adjustment Step (EIS5):

Setpoint adjustment step for adjusting by setpoint adjustment input.

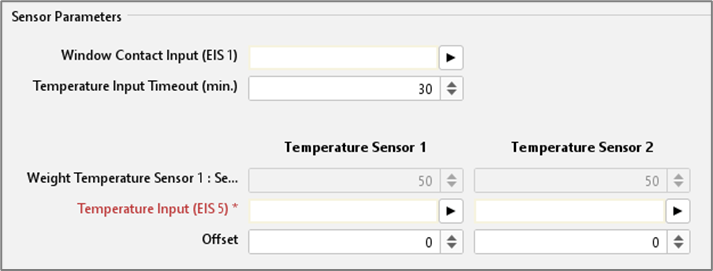

Sensor Parameters

Window Contact Input (EIS1):

By way of window contact input, RTR automatically changes into mode of frost or heat protection. To this object, either it can`t be sent no EIS1 telegrams. Every value unlike “0” will be interpreted as one open window.

Job Editor Classic - RTR sensor parameters

Temperature Input Timeout (min):

After that defined period of time, a temperature sensor will be tagged as defective, as far as it doesn`t send no longer any telegrams. RTR will switch into failure mode.

Weighting Temperature sensor1: sensor2:

If more than one temperature sensor is registered, weighting of both can be defined here. Normally both sensors should be weighted equally, but according to their assembly site another weighting can be useful.

Temperature Input (EIS5)

In this object group address for the EIS5 temperature sensor has to be entered.

Offset:

In case temperature sensor isn`t calibrated correctly, it can be corrected by offset.

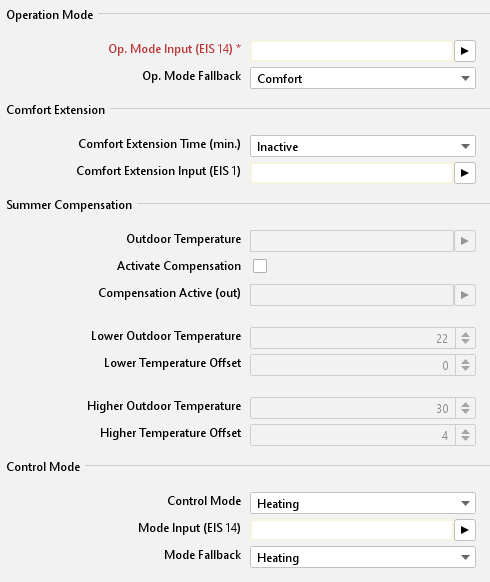

Operation Mode

Operation Mode Input (EIS14):

Mode of operation can be altered by this object, using the visualization object RTR display. Various modes of operation can be adjusted.

1: Comfort

2: Standby

3: Night Setback

4: Frost-/ Heat Protection

Example: By sending of EIS 14 value 1, you will change to operation mode Comfort.

By sending of EIS 14 value 3, you will alter to operation mode Night Setback.

Operation Mode Fallback:

If object operation mode input will receive one undefined value, RTR will use this fallback mode.

Job Editor Classic –RTR operation mode, comfort ext., summer compensation., control mode

Comfort Extension

Comfort Extension Time (min.):

Within this defined period of time, RTR will remain in operation mode „comfort“ in case comfort extension is enabled - and mode of operation should change from comfort to another.

Comfort Extension Input (EIS1):

By this object, comfort extension can be enabled or disabled.

Summer compensation

Outdoor Temperature:

Input object of the outdoor temperature sensor.

Activate Compensation:

Before using of compensation option has to be activated.

Compensation Active (out):

Output object over state of summer compensation

Higher and Lower Outdoor Temperature:

Via lower and Higher outdoor temperature, it will be defined, from which and until which temperature value a setpoint readjustment for summer compensation will be performed.

Higher and Lower Temperature Offset:

With the help of lower and Higher temperature offset it is defined, by how many Kelvins adjusted setpoint will be raised during summer compensation.

Control Mode

Control Mode:

Functions which could be selected are:

Cooling/Heating Automatic: at this place RTR decides on operation mode Heating or cooling.

Cooling/Heating Manual: at this place operation mode is preset for RTR.

Heating

Cooling

When changing the operating mode between heating and cooling, the outputs for the control values are initially switched off. The control only becomes active again in the next control cycle and calculates new control values according to the selected operating mode.

Mode Input (EIS14):

By operation mode input, following working modes can be defined:

Off (value 0)

Heating (value 1)

Cooling (value 2)

Comfort extension (value 3)

Example: By sending of an EIS 14 value 2, you will change to Control mode cooling.

Mode Fallback:

If in operation mode input one invalid value was received, RTR will change to configured fallback operation mode.

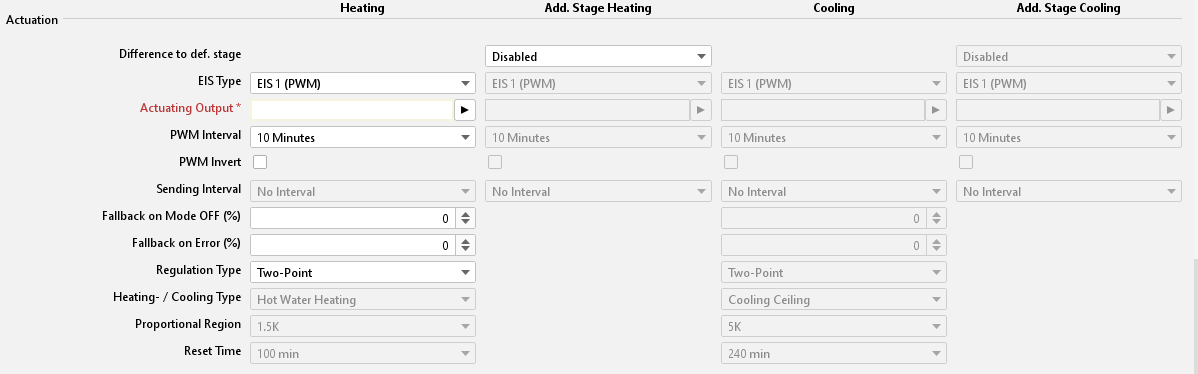

Actuation

Editor Classic – RTR control variable

Distance to def. stage:

The application of an additional heater and/or cooling device is possible. In case of greater variance of nominal to actual temperature, room can be heated up or cooled down faster by hooking up of the additional level.

Actuating output (EIS1, EIS5, EIS6):

Current control variable will be sent to this output as one EIS 5 value. By using EIS 1, value will be 0 or 1, resp. by EIS6 0% to 100 %.

Note: Please consider that the group addresses of heating or cooling will differ.

Fallback on Mode Off (%):

In case operation mode will change to “out”, stated control variable will be transmitted at this point.

Fallback on error (%):

In case of error predefined control variable will be sent out. It is about one case of error, when no actual temperature will be received or invalid values are sent to object operation mode.

Note: Depending on control algorithm, different inputs are necessary. All not relevant input options in this case are disabled.

Switching PI Control (PWM)

EIS Type:

EIS 1 (switching, 1Bit)

If EIS 6 is selected for output, the value 0% and 100 % will be sent out.

If EIS 5 is selected for output, the value 0 or 1 will be transmitted.

PWM Interval:

PWM interval defines the switching frequency of the pulse range modulated signal and allows the adaptation to the adjusting cycle times of used actuators. (Traversing time the actuator requires to adjust the valve from a completely closed position to a completely opened position).

Control variable transmits Out, On, value 0/1.

PWM Invert:

For adaptation to several actuators, control variable can be inverted. In this case control variable transmits Out, On, value 1/0.

Regulation-Type:

For execution of PVM, PI will be selected.

Heating/ Cooling-type:

There is the possibility to select predefined configurations or to enter values of proportional region and reset time manually.

Heating | Cooling |

|

|

Proportional Region:

Adjusting the constant P part of PI control. Choices from 1 to 10 Kelvin.

Reset Time:

Adjusting the variable, I part of PI control. Choices from 0 to 240 minutes.

Continuous PI Control

EIS Type:

EIS 6 (percent 0-100%, 1 Byte)

Transmission interval control variable:

Setting the transmission interval of control variable from 3 to 30 minutes.

Regulation-Type:

For execution of continuous PI-control, PI will be selected.

Heating/ Cooling-type:

There is the possibility to select predefined configurations or to enter values of proportional region and reset time manually.

Heating | Cooling |

|

|

Proportional Region:

Adjusting the constant P part of PI control. Choices from 1 to 10 Kelvin.

Reset Time:

Set the variable I portion of the PI control. Selections from 0 to 240 min

Two Point control

EIS type:

EIS 1 (switching, 1Bit)

Regulation-Type:

For execution of the two-step control, two point will be selected.

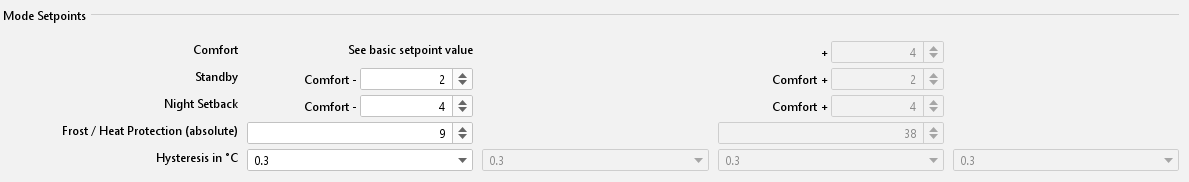

Mode Setpoints

Job Editor Classic – RTR modus setpoints

Comfort

Comfort temperature for heating is defined by the basic setpoint. Comfort temperature for cooling is indicated relatively to the basic setpoint.

Standby:

The value of standby refers relatively to the nominal setpoint of heating resp. Cooling; for heating the nominal setpoint will be reduced by this value, for cooling the nominal setpoint will be raised by this value.

Night Setback:

The value for night setback refers relatively to the setpoint for heating resp. cooling.

Frost-/Heat Protection (absolute):

The temperature for frost- or heat protection is specified absolutely in degrees Celsius, heating or cooling will be activated then automatically.

Hysteresis in °C (only for two-point control):

The value of hysteresis defines, when RTR starts to heat. A value of o,3 signifies, that RTR start to heat from a actual temperature of 19,7 °, in case of a predefined nominal temperature of 20° C. If reaching the nominal temperature, control variable will be reset to 0.

Application example

RTR job – application example